|

|

|

Lead |

|

| The

lead ore most commonly mined in galena, which is the sulphide

of lead (PbS). It forms intimately mixed with other metalliferous

minerals, such as sphalerite (zinc sulphide), cooper pyrites

and iron pyrites. The ore has to be concentrated, e.g., by

flotation, in order to separate the galena from the sphalerite

and other minerals that may be present. |

|

| Lead

has been commonly used for thousands of years because it is

widespread, easy to extract and easy to work with. It is highly

malleable and ductile as well as easy to smelt. Metallic lead

beads have been found in Çatalhöyük dating

back to 6400 B.C. In the early Bronze Age, lead was used with

antimony and arse. |

|

| Lead

also refers collectively to the organic and inorganic compounds

of lead, which are toxic. Lead poisoning was documented in

ancient Rome, Greece, and China. In the 20th century, the

use of lead in paint pigments was sharply reduced because

of the danger of lead poisoning, especially to children. By

the mid-1980s, a significant shift in lead end-use patterns

had taken place. Much of this shift was a result of the U.S.

lead consumers' compliance with environmental regulations

that significantly reduced or eliminated the use of lead in

non-battery products, including gasoline, paints, solders,

and water systems. |

|

|

|

| Lead

use is being further curtailed by the European Union's RoHS

directive. Lead may still be found in harmful quantities in

stoneware, vinyl such as that used for tubing and the insulation

of electrical cords, and brass manufactured in China. Between

2006 and 2007 many children's' toys made in China were recalled,

primarily due to lead in paint used to color the product. |

|

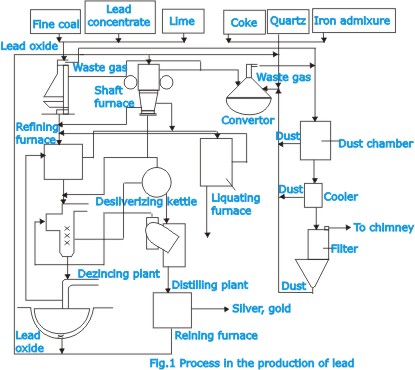

| Subsequent

treatment of the concentrate thus obtained consists in roasting

followed by reduction in a vertical-shaft furnace, a form

of blast furnace. Roasting is basically performed by heating

the lead ores, blended with suitable fluxing minerals, on

a traveling endless grate through which air is sucked. In

this way the material is sintered converted into lumps called

sinter, which are then mixed with coke and charged into the

shaft furnace (Fig.2). Air is forced into the furnace at the

bottom. |

|

|

The

coke, which uses as fuel and reducing agent, reacts with the

sinter to reduce the oxides and yield liquid lead, which is,

however, contaminated with other metals like silver, copper,

zinc, tin, antimony, bismuth, arsenic, etc. The non reduced

components form a liquid slag which floats on the liquid metal.

Preparing the charge and operating the furnace call for great

skill. In particular, the charge must contain the correct

proportions of iron, lime and silica to produce a liquid slag

that can readily be separated from the metal; it is also essential

to maintain the proper balance of coke and sinter.

|

|

| |

|

| When

the impure liquid lead (bullion) cools, some of the impurities,

especially copper, separate out as drosses, which are further

processed to extract the copper. Further removal of the copper

may be effected by treatment of the bullion with sulphur.

Antimony, tin and arsenic are removed by elective oxidation

in a reverberatory furnace or by treatment of the bullion

with chemical reagents to separate out these metals in the

form of salt-type compounds. |

|

| On

cooling, the zinc forms a dross or crust which contains nearly

all the silver and other metallic impurities. The dross is

skimmed off, and the silver is recovered from it in a separate

process. The zinc is distilled off and used over and over

again (Fig.3). After desilverizing, the lead may have to be

debismuthized, which is done by a process somewhat like desilverizing

but using calcium and magnesium instead of zinc to form dross

with the bismuth. |

|

|

An

alternative method of treating the impure bullion is by electrolytic

refining. The bullion is cast into plates which serve as anodes

in electrolytic tanks. The electric current causes the lead

at the anode to dissolve, and pure lead is deposited at the

cathode. All these refining processes can produce pig lead

of very high purity (99.999%). |

|

|

o

DISCLAIMER o

CONTACT US |

|

|

|