Mine Ventilation |

|

|

In

between 4000 and 1200 BC, European miners dug tunnels into

chalk deposits searching for flint. Archaeological investigations

at Grimes Graves in the south of England have shown that these

early flint miners built brushwood fires at the working faces

presumably to weaken the rock. However, those Neolithic miners

could hardly have failed to observe the currents of air induced

by the fire. Indeed, the ability of fire to promote airflow

was rediscovered by the Greeks, the Romans, in medieval Europe

and during the Industrial Revolution in Britain. |

|

| The

Laurium silver mines of Greece, operating in 600 BC, have

layouts which reveal that the Greek miners were conscious

of the need for a connected ventilating circuit. At least

two airways served each major section of the mine and there

is evidence that divided shafts were used to provide separate

air intake and return connections to the surface. Underground

mines of the Roman Empire often had twin shafts, and Pliny

(AD 23-79) describes how slaves used palm fronds to waft air

along tunnels. |

|

| Ventilation

in a mine serves three main purposes: (a) to provide fresh

air for respiration by the miners, (b) to dilute any noxious

gases that may be formed underground and (c) to lower natural

heat of the rock. The underground temperature rises with increasing

depth-on an average about 1oC for every 30m (100ft.)- so that

the deeper the mine, the hotter is generally is.

|

|

|

|

| In

simple horizontal-tunnel mining it is usually sufficient to

rely on natural ventilation by utilizing the difference in

air pressure associated with the difference in level between

two openings – the mine entrance and the top of a ventilation

shaft (Chimney effect, Fig.1). Depending on the external temperatures

prevailing at different times of the year, the direction of

flow of the draft is subject to change.

|

|

| Diffusion

(as distinct from draft) also plays some part in changing

the air in a tunnel; thus, a large-diameter tunnel can be

driven to a distance of several hundred feet without requiring

artificial ventilation. The exhaust air from pneumatic tools

is also helpful in promoting air circulation.

|

|

| In

deep mining it is necessary to use fans, that is also of very

large size. In large coal mines fresh air may have to be drawn

in at a rate of 20,000 m3 (7,00,000 ft3) per minute. These

fans are installed at the air-extraction shafts at the edge

of the mined area the main winding shaft or shafts, through

which the fresh air is drawn in, being located in the central

part of this area. With every method of ventilation the above

mentioned chimney effect is utilized as fully as possible:

the fresh air descends by gravity to the lowest levels of

the mine and is heated by the natural heat of the rock, so

that it becomes specifically lighter and tends to rise.

|

|

| |

|

|

|

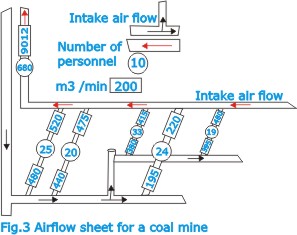

| The

rising air makes its way by various paths to suction zone

of the main extraction way or shaft, in which suction pressure

up to 400mm (17 in) water gauge are maintained. Distribution

of the fresh air over the various levels, main roadways, crossnuts,

rooms and workings is assisted by ventilation doors (designed

as air locks), stoppings, air crossings and other devices

(Fig.2 and 3).

|

|

|

|

| Planning

of a mine-ventilation system includes the preparation of so

called air-flow sheets-diagrams comprising data on airflow

conditions. These diagrams are prepared for each section and

for the mine as a whole, the data being checked against measurements

of the actual flow underground.

|

|

For

reasons of safety the main flow has to be split up into the

largest possible number of circulating currents, and it is

essential to prevent “short circuits” –

circumstances causing the air to take a shortcut and thus

bypass certain parts of the mine. Parts that are not accessible

to the natural ventilation have to be provided with auxiliary

ventilation. For this purpose air is piped to those parts

through large-diameter ducts through which it is impelled

by powerful fans. |

|

|

|

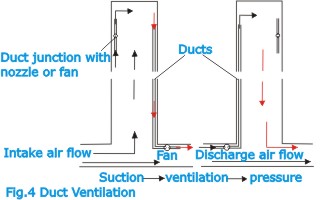

| This

auxiliary ventilation possesses a separate system whose proper

functioning has to be supervised and controlled with considerable

care. It may operate by suction or by pressure (blowing) or

a combination of both (Fig 4). Particularly in deep and hot

mines e.g., in South African gold mining – air conditioning

(as distinct from mere ventilation) may be used to maintain

the atmosphere of the workings at suitable temperature and

humidity for men to work in. Because of the high cost involved,

it is seldom used, however.

|

|

|

o

DISCLAIMER o

CONTACT US |