Nitric Acid |

|

|

For

a long time all nitric acid (HNO3) used to be produced from

nitrates occurring in nature. For example, nitric acid can

be obtained by adding sulphuric acid to saltpeter (potassium

nitrate), whereby the latter undergoes decomposition.

|

|

| In

the pure state the acid is a colorless liquid which boils

at 87 oC. The boiling point rises with increasing dilution.

As pure nitric acid will always undergo some decomposition

when left to stand, especially when exposed to the action

of light, acid with a concentration exceeding 90% almost invariably

contains some dissolved NO2. This decomposition process can

be stopped by diluting the acid with water. |

|

|

|

| Nitric

acid produces a very convincing aged effect on maple and especially

on pine. It is an extremely dangerous chemical to work with

full-strength, so basically recommend 10-20% solution. After

applying the nitric acid, heat the wood with an electric heat

gun to develop the color effect. Then neutralize the nitric

acid with a solution of baking soda dissolved in water. Allow

at least one week drying time before finishing.

|

|

|

|

| The

various processes for the commercial manufacture of nitric

acid are based on any of three principles: the decomposition

of nitrates more particularly Chile saltpeter with sulphuric

acid: the direct synthesis of NO from nitrogen and oxygen

in an electric arc, followed by the last two reactions of

the ammonia process or the catalytic oxidation of ammonia.

|

|

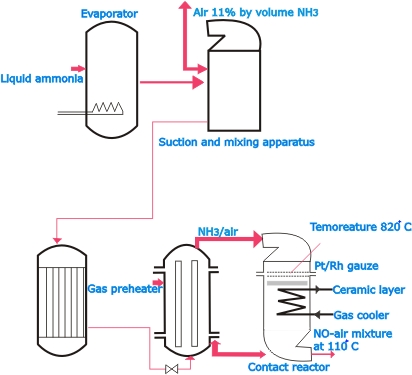

| The

ammonia process is now most widely employed, more particularly

with platinum as the catalyst. In certain variants of the

process the catalyst may, however, be Fe2O3, Mn2O3 or Bi2O3.

In this process liquid ammonia is vaporized in an evaporator

and is mixed with air. The gas mixture (10% ammonia and 90%

air) makes its way through a filter and a preheater to the

contact reactor, in which it passes over platinum gauze (the

catalyst) heated initially to about 900 oC. Heat liberated

in the reaction maintains the temperature of the catalyst.

In the reactor about 90% of the ammonia is oxidized to nitric

oxide: 4NH3 + 5O2 -> 4 NO +6H2O

|

|

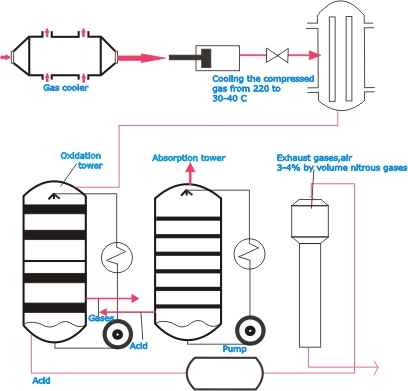

| Directly

after the platinum gauze are filtering agents which trap the

unstable platinum compounds present in the gas discharged

from the reactor: the platinum precipitated in this way is

recovered. This gas, of which 97 ½% is NO, is cooled

in the gas cooler. On leaving the cooler, it is passed through

absorption towers, filled with rings made of ceramic material,

in which two reactions take place. In the first tower the

nitric oxide is oxidized to nitrogen dioxide. 2 NO+O2 ->

2 NO2. In the following towers (four in all) the dioxide reacts

with water to form nitric acid: 3 NO2 +H2O -> 2 HNO3.

|

|

| |

|

| The

requisite water is added in the last tower. In the preceding

towers the NO2 is brought into contact not with water, but

with nitric acid solution, which is circulated by pumps and

passed through cooling apparatus to remove the heat evolved

in the reaction, as low temperatures are favorable to the

absorption reactions. In a degasifying tower air is blown

through the acid to remove such amounts of NO gas as are still

present in it. The exhaust gas from the final absorption tower

contains 0.3 to 0.4 % NO.

|

|

| The

installation described here produces nitric acid in a concentration

of between 40 and 60%. A higher concentration (Upto 99.5%)

is obtainable by distillation with concentrated sulphuric

acid. Nitric acid is used in the manufacture of fertilizers,

explosives, lacquers, dyes, plastics and synthetic fibers.

|

|

Alone,

it is useful in metallurgy and refining as it reacts with

most metals, and in organic syntheses. When mixed with hydrochloric

acid, nitric acid forms Aqua Regia, one of the few reagents

capable of dissolving gold and platinum. |

|

| Nitric

acid is a powerful oxidizing agent, and the reactions of nitric

acid with compounds such as cyanides, carbides, and metallic

powders can be explosive. Reactions of nitric acid with many

organic compounds, such as turpentine, are violent and hypergolic

(i.e., self-igniting). Concentrated nitric acid dyes human

skin yellow due to a reaction with the keratin. These yellow

stains turn orange when neutralized. |

|

|

o

DISCLAIMER o

CONTACT US |