Phosphorus |

|

|

Phosphorus

was discovered by German alchemist Hennig Brand in 1669 through

a preparation from urine, which contains considerable quantities

of dissolved phosphates from normal metabolism. Working in

Hamburg, Brand attempted to create the infamous Philosopher's

stone through the distillation of some salts by evaporating

urine, and in the process produced a white material that glowed

in the dark and burned brilliantly. Since that time, phosphorescence

has been used to describe substances that shine in the dark

without burning.

|

|

| Phosphorus

was recognized as a chemical element at the emergence of the

atomic theory that gradually occurred in the late part of

the 18th century and the early 19th century, and was formulated

by John Dalton.

|

|

| Phosphorus

was first made commercially, for the match industry, in the

19th century, by distilling off phosphorus vapor from precipitated

phosphates heated in a retort. The precipitated phosphates

were made from ground-up bones that had been de-greased and

treated with strong acids. This process became obsolete in

the late 1890s when the electric arc furnace was adapted to

reduce phosphate rock.

|

|

|

|

|

|

| Phosphorus

occurs in nature only in the form of the salts of phosphoric

acid. From these it is obtained by reduction. There are three

allotropic forms of elementary phosphorus: white, red and

black. Of these, black phosphorus is the form that is most

stable at room temperature; it is obtained from the white

form by the application of high pressures.

|

|

| Black

phosphorus is mainly of scientific interest, whereas the other

two allotropic forms are technically important. White phosphorus

melts at 44.1°C, when finely divided, reacts with atmospheric

oxygen even at room temperature. Red phosphorus is obtained

from white phosphorus by heating the latter in a closed container.

|

|

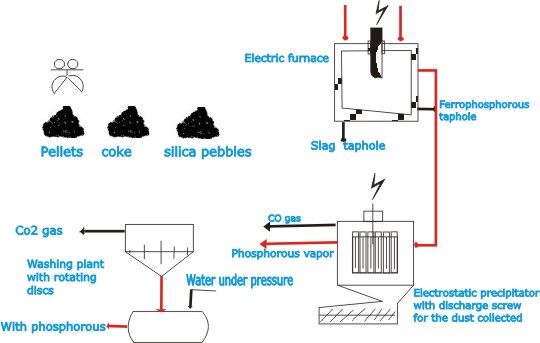

| Phosphorus

is prepared by heating calcium phosphate with carbon and silica

(SiO2) in an electric furnace. The reaction is represented

by the following equation:

2Ca3(PO4)2 + 6SiO2 +10 C -> 6Ca SiO4+P4+10 CO

|

|

| |

|

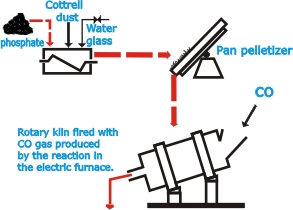

| The

phosphate is fed to the furnace in lump form. To make them

suitable for processing in this way, finely granular phosphates

first have to be agglomerated by palletizing. Agents used

for binding the particles together into pellets are soda water

glass (sodium silicate), Cottrell dust obtained from electrostatic

precipitation processes and other admixtures, which are intimately

mixed with the phosphate grains in a screw mixer and then

palletized in a revolving pan. The pellets are transformed

to firm, hard balls (nodules) by sintering at high temperatures

in rotary kilns or on special sintering grates. The nodules,

mixed with coke and silica pebbles, are fed to the furnace.

|

|

| The

three-phase electric furnace consists of a steel tank of which

the bottom part is lined with hard-burned carbon blocks and

the top part with fireclay bricks. At the bottom are two tapholes

for tapping the ferrophosphorus and the slag respectively.

The furnace cover is provided with openings for the three

electrodes, the feed pipe and the gas outlet. The electrodes

are made of carbon and are fed from above at a rate sufficient

to compensate for loss by burning. |

|

| The

gas discharged from the furnace, consisting of phosphorus

and CO, is passed through Cottrell-type electro-static dust

precipitators (dust filters) in which the dust in the gas

is trapped and collected. These precipitators are heated to

prevent condensation of phosphorus inside them. The dust is

returned to the sintering plant. |

|

| The

exit gases, which have a temperature of 250° –350°

C, are passed to Stroder washers in which the phosphorus is

condensed. The white phosphorus obtained in this process is

stored under water to prevent the spontaneous combustion that

results from contact with air. The CO gas that is discharged

from the washers is utilized for heating the sintering plant

and steam boilers or is burned at the top of high flare stacks.

|

|

| Phosphorus

is used in the manufacture of detergents. The plastics industry

uses phosphorus-based plasticizers. Red phosphorus is employed

in the friction striking surfaces on match boxes. |

|

|

o

DISCLAIMER o

CONTACT US |