Precautions Against Mine Gas |

|

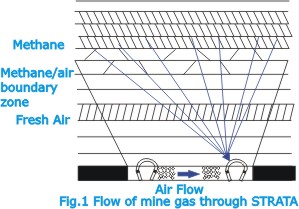

| For

every ton of coal removed from the working face, anything

up to 200 m3 (7000 ft3) of mine gas is released; the average

amount in the Ruhr coal-mining district is 30 m3 (about 1000

ft3). This gas consists of hydrocarbons, chiefly methane (CH4)

and is known as firedamp, more particularly when it occurs

in an explosive mixture with air (when the gas concentration

in the air is between 4.5 and 14.5%). Methane is a colorless,

odorless, and tasteless gas.

|

|

| Firedamp

explosions have been the cause of many catastrophes and a

vast number of deaths in the history of coal mining. The initial

explosion is liable to ignite the cloud of coal dust that

the blast disperses. When the air contains between 700 and

1000 grams of coal dust per cubic meter, it constitutes an

explosive mixture. A coal-dust explosion produces carbon monoxide

(CO), which is a serious danger to human life because of its

toxicity.

|

|

|

|

| Accordingly

the main object of research, supervision and legislation relating

to safety in coal mines is to develop and improve the precautions

against the occurrence of such mishaps. Essentially, the aim

is to eliminate all possibility of ignition of such explosive

mixtures. The emission of gas from the coal is a natural phenomenon

associated with the constitution of the coal and adjacent

strata (Fig.1), and except in some rare circumstances where

methane gas can be removed in advance by suction, it is not

possible to reduce or effectively control this emission.

|

|

| The

application of special procedures in extracting the coal,

high speed of advance at the coal face, complete sealing off

of old workings by suitable stowing (backfilling), etc., may

have a favorable effect. It nevertheless remains essential

to conform closely to safety regulations and to take all manner

of technical precautions to prevent the occurrence of any

spark or flame that might set off an explosion, including

a strict ban on smoking. There remain potential sources of

ignition in the use of explosives and electricity underground.

Frictional heating of machinery and spontaneous-combustion

phenomena, which may arise under certain conditions are also

hazards.

|

|

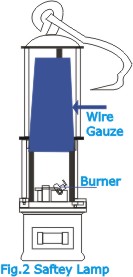

| An

effective measure consists in keeping the workings supplied

with fresh air in quantities large enough to ensure that the

mine-gas concentration will at all times remain below the

explosive level. The first important development in overcoming

the firedamp menace was the invention of the safety lamp by

Davey in 1816.

|

|

| |

|

|

|

| The

lamp which burns a liquid fuel is provided with an enclosure

of metal-wire gauze above the glass (Fig.2). If the air surrounding

the lamp contains mine gas, the flame of the lamp will ignite

the gas, but the latter will burn only inside the gauze enclosure;

the flame will not ignite the gas all round the lamp. It is

the high thermal conductivity of the gauze that arrests flame

propagation. |

|

|

|

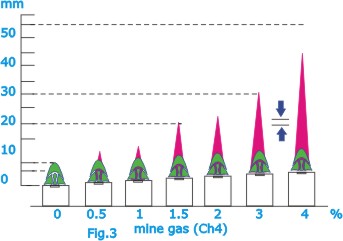

| The

lamp is used today as a detector for gas, which burns with

a characteristic flame called a gas cap that appears when

the flame in the lamp is lowered. The length of the gas cap

provides an indication of the percentage of gas in the air

(Fig.3). A countermeasure against the formation of highly

inflammable and therefore explosive coal-dust clouds consist

in dusting i.e., specified quantities of stone dust are deposited

throughout the mine, more particularly just before blasting

is to take place. |

|

|

|

|

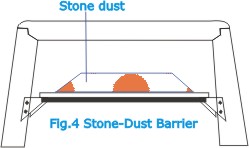

The

cloud of dust thrown up by the explosion is rendered nonflammable

by the presence of the stone dust. Stone dust is also used

as a means of arresting the propagation of explosions. For

this purpose a device called a stone-dust barrier (Fig.4)

is installed at strategic points in the mine. It may take

the form of a light tilting platform on which a quantity of

stone dust is placed. In the event of an explosion in the

vicinity, the dust is flung off and forms a dense cloud which

absorbs some of the energy of the blast and also exercises

a cooling action which smothers the flame. |

|

|

o

DISCLAIMER o

CONTACT US |