Preparation of Ores |

|

|

Metalliferous

ores straight from the mine are seldom directly suited for

metal smelting. Quite often their metal content is too low

e.g., only 0.8% copper or 5% lead for processing in the furnace,

or they may be composed of minerals containing different metals

requiring different kinds of metallurgical treatment.

|

|

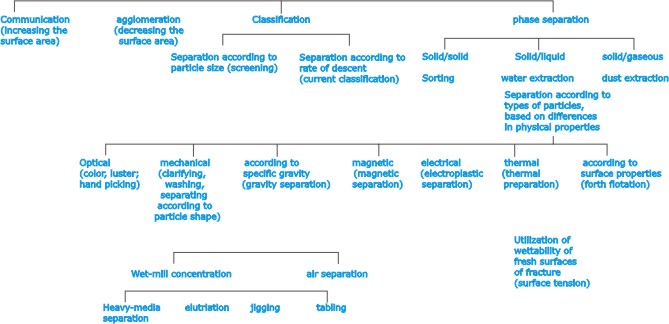

| For

these reasons, must ores have to undergo variety of preparatory

processes, referred to as dressing for the removal or separation

of waste matter or other minerals, so that the concentration

of the desired mineral is increased. Some of the processes

used more particularly in ore dressing are sorting; comminution

(crushing and grinding); sizing (by screening); classifying

(e.g., the grading of finely divided material by rates of

settling); separation (e.g., by magnetism, electrical conductivity,

specific gravity, etc.). |

|

|

|

| The

preparation plants are basically situated at the mines, so

that only the processed ore, free of waste matter, has to

be transported to the smelting works. Preparation starts with

crushing and grinding (Fig.1). The degree of comminution (size

reduction) to be applied will depend on the size of the ore

lumps and on the requirements of the subsequent treatment

to be applied. Sizing and classifying i.e., grading the comminuted

material according to particle size are important operations

in ore dressing. To relieve the crushing and grinding machines

of unnecessary load, particles that have been sufficiently

reduced in size are removed by screening (Fig.5).

|

|

|

Sizing

of relatively coarse particles can most efficiently be performed

by screening, and screens of many kinds are used for the purpose.

Small particles below about 1mm in size can usually be more

suitably sized by classification based on different rates

of settling of different particles sizes in water. For e.g.

the Hardinge countercurrent classifier (Fig.6) is slowly rotating

drum on the inner surface of which are located spiral flanges.

As the classifier rotates, the coarser particles are settled

out, moved forward by the spiral flanges, and repeatedly turned

over in a forward motion, releasing any finely divided material

mixed with them. |

|

| It

is not possible, within the scope of this article, to describe

all the many processes and types of equipment employed in

the preparation of metalliferous ores. However, three important

methods of treatment will be dealt with. |

|

| |

|

| In

wet-mill concentration the differences in specific gravity

of different minerals are utilized for separating them. The

metalliferous ores – sulphides and oxides – are

as a rule specifically heavier than the waste material. Separation

of the ore from the waste may be effected in a settling classifier

with the aid of water in motion, the underlying principle

being that the differences in specific gravity are associated

with different rates of settlement of the particles (Figs.

2 and 7).

|

|

| Coarser

particles, ranging in size from about 0.5 to 30 mm, can be

settled out in a machine known as a jig in which a horizontal

stream of water is subjected to a rhythmical up-and-down motion.

Finer-grained materials, approx. 0.3 to 0.5 mm in size may

be treated on a table concentrator a slightly inclined plate

on which the lighter material is separated from the heavier

by a thin, shallow stream of water. |

|

| This

hydromechanical separating action may be augmented by the

action of gravity developed by oscillating or jolting motions

applied to the table (shaking and bumping tables Fig.4) these

concentration processes are referred to as tabling. |

|

Flotation

is an important and commonly used separation process which

is based on the fact that some of the components in the comminuted

minerals are wettable, whereas others are water-repellent

(hydrophobic Figs 3 and 8). The hydrophobic particles have

an ability to hold air bubbles by surface action, the nature

of the film on the outside of the particles being the controlling

factor. |

|

Finely

divided air which is introduced into the pulp the mixture

of solids and water in which flotation is performed, adheres

in the form of bubbles to these particles, more particularly

the metalliferous components of the pulp, and causes them

to rise to the surface. Here they collect in a mass of froth

and are removed by a skimmer device. The hydrophilic components

remain behind in the pulp. As a rule, these are the worthless

minerals (gangue), which are removed as tailings from the

flotation machine.

|

|

The

sulphides of heavy metals are readily floatable, and flotation

is therefore an important method for the concentrating of

copper, lead and zinc ores. A further development has been

the selective flotation of two or more useful minerals, particularly

the ores of different metals, which can thus be collected

as separated concentrates This principle is, for example,

applied to the preparation of sulphidic lead-zinc ores.

|

|

The

floatability of minerals can be controlled by certain chemical

additives called flotation agents. These are of various kinds:

Frothers, whose function is to produce froth by combining

the air bubbles into a stable froth which will buoy up the

ore particles. Oils and allied substances are used as frothers.

|

|

Collectors

are substances that increase the water repellency and make

the ore particularly receptive to the attachment of air bubbles.

Collectors usually consist of synthetic organic compounds.

|

|

Other

flotation agents help to regulate the process. Other depressors

can make hydrophobic minerals temporarily hydrophilic and

can in this way help in the selective separation of one mineral

from another by depressing one, thereby inhibiting its flotation.

The depressed mineral can subsequently be made hydrophobic

again by an activating agent. The various agents for regulating

the flotation process in this manner are inorganic compounds,

mostly salts. |

|

| Magnetic

separation: If a comminuted and classified ore is brought

into a magnetic field, the magnetic components generally the

useful metalliferous ore can be extracted and thus separated

from the nonmagnetic residual material. The treatment is carried

out with the aid of magnetic separators, of which there are

many kinds. |

|

A

drum separator is explained in Fig.9. This method of separation

plays an important part, for example, in the concentrating of

certain iron and manganese ores. Those substances which are

attracted by a magnetic field are called paramagnetic. These

are subdivided into strongly magnetic and weakly magnetic substances.

|

|

| Various

techniques have been applied for the separation of both categories

of material. In general, magnetic fields of greater intensity

high intensity magnetic separators have to be employed for

dealing with weakly magnetic ores. In both categories wet

and dry processes are employed, depending on whether or not

water is used as an aid in the process.

|

|

| The

magnetic properties of certain ferrous minerals can be enhanced

by suitable preliminary heat treatment. For instance, in the

case of siderite a particular kind of iron ore, which is a

carbonate-FeCO3 the carbon dioxide can be expelled by heating

the ore in a kiln. As a result, the carbonate is converted

into the strongly magnetic compound named ferroso-ferric oxide

(Fe3O4), which can readily be separated by a magnetic action.

|

|

|

o

DISCLAIMER o

CONTACT US |