Plastics Processing |

|

|

The

properties of plastics and the many different requirements

depending on finished products made from them have led to

the development of a number of methods for shaping and molding

these materials. From the manufacturers who synthetically

produce plastics for industrial use the fabricating industry

obtains the specified initial materials, i.e., the appropriate

polymers with or without the requisite additives. |

|

|

|

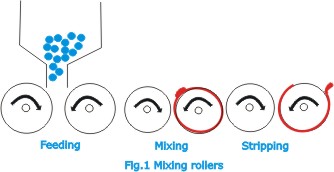

| In

the latter case the user will have to add auxiliary materials

such as plasticizers, stabiliziers, pigments and fillers.

Batch mixing of powdered ingredients is performed in agitators

or mixing drums. Alternatively, kneaders or mixing rolls (Fig.1)

are used for plastifiable materials. The last mentioned device

comprises a pair of rollers which revolve in opposite directions

and which can be heated or cooled as required. |

|

| The

material entering the gap between the rollers is squeezed

and mixed. On completion of this treatment the so-called rough

sheet is stripped from the rollers (Fig.1) and passed to a

further stage of processing. Continuous mixing is performed

in extruders, which offer the additional advantage of filtering

the plastics before they undergo further processing (Fig.4). |

|

|

|

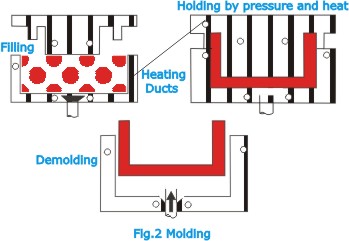

| The

shaping of plastic articles and components without the application

of pressure is effected by casting. The simplest method of

shaping in conjunction with pressure is by molding (Fig.2),

which is suitable for both thermosetting and thermoplastic

compositions. Thermoplastics can be softened by the application

of heat; thermo setting plastics undergo chemical change under

the action of heat and are thereby converted to infusible

masses which cannot be softened by subsequent heating. |

|

|

|

| The

Plastic Processing programme has been drawn up by the Finnish

plastics industry, the universities and Tekes with the aim

of improving the competitiveness of companies developing injection

moulding, and manufacturing and using injection-moulded components.

The programme is finished. |

|

| The

aim of the entire programme was to improve the competitiveness

of the companies in the business chain. This was achieved

by speeding up the product development process, the mould

manufacturing process and making them more efficient and by

controlling the production process considerably better than

at present. An additional goal was to improve mould performance,

speed up start-up times for production processes and minimize

environmental impacts. |

|

|

|

| Another

method of producing molded articles is by injection molding

(Fig.5), which has the advantage over ordinary molding that

preheating, plasticizing, and shaping are done by the same

machine. The only materials suitable for injection molding

are thermoplatics of high fluidity. The granules are introduced

through a hopper into the cylinder, in which they are heated-by

means of a heating jacket- to above their softening point.

A moving piston plasticizes the material and forces it through

a nozzle into the mold. The plasticizing action can be enhanced

by the use of a screw instead of a piston (Fig.6).

|

|

| |

|

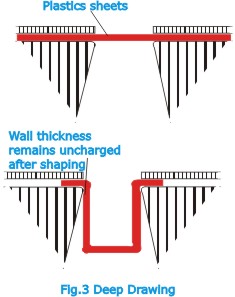

| Articles

or components can also be shaped by the machining of semifinished

products films, sheets, rods or tubes. Machining is more particularly

employed in cases where the articles are of complex shape

or where only a small number are required. Whereas thermosetting

plastics can be shaped only by machining (milling, turning,

cutting, drilling) once they have hardened, semifinshed thermoplastic

materials can be shaped by heating and joined by welding.

Hot shaping of thick sheets can be effected by bending or

drawing (Fig.3). In the drawing process the material to be

shaped is gripped, heated and deformed to the desired shape.

If the wall thickness must remain constant, the sheet must

be resiliently gripped; with so-called stretch forming a reduction

in wall thickness occurs. |

|

In

recent years shaping by the vacuum process has gained importance.

In the female-mold method or negative mold method, the heated

plastic sheet is laid on a concave mold and subjected to further

heating. Air is extracted through holes in the mold, so that

the sheet is drawn by suction into the mold. For the molding

of complex components the plate is prestretched before the actual

negative molding operation begins.

|

|

Alternatively,

a convex master model may be used, in which case the process

is known as the male-mold method or positive-mold method. The

preheated sheet is placed over the master model and preformed.

When the air is evacuated, the desired shape is obtained. The

molding techniques are schematically illustrated in Figs.8 and

9.

|

|

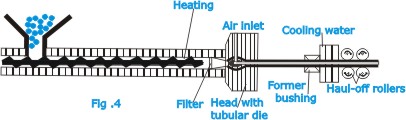

Endless products such as sections, sheet, strip and thin are

produced by extruders (Figs. 4 and 6). Extrusion consists

in forcing a plastic material through a suitably shaped die

to produce the desired cross-section shape. The extruding

force may be exerted by a piston or ram (ram extrusion) or

by a rotating screw (screw extrusion) which operates within

a cylinder in which the material is heated and plasticized

and from which it is then extruded through the die in a continuous

flow.

|

|

Different

kinds of die are used to produce different products e.g.,

blown film formed by blow head for blown extrusions, sheet

and strip slot dies and hollow and solid sections i.e. circular

dies. Wires and cables can be sheathed with plastics extruded

form oblique heads. The extruded material is cooled and is

taken off by means of suitable devices which are so designed

as to prevent any subsequent deformation.

|

|

For

the manufacture of large quantities of film or thin sheet, the

sheeting calender is employed (Fig.7). The rough sheet from

the two-roll mill is fed into the gap of the calender, a machine

comprising a number of heatable parallel cylindrical rollers

which rotate in opposite directions and spread out the plastics

and stretch the material to the required thickness.

|

|

The

last roller smoothes the sheet or film thus produced. If the

sheet is required to have a textured surface e.g., to resemble

wood graining, the final roller is provided with an appropriate

embossing pattern; alternatively, the sheet may be reheated

and then passed through an embossing calender. The calender

is followed by one or more cooling drums. Finally the finished

sheet or film is reeled up.

|

|

| Another

field of application consists in coating a supporting material

e.g., textile fabrics, paper, cardboard, metals, various building

materials with plastics for the purpose of electrical insulation,

protection against corrosion, protection against the action

of moisture or chemicals, providing impermeability to gases

and liquids, or increasing the mechanical strength. Coatings

are applied to textiles, foil and other sheet materials by

continuously operating spread-coating machines (Fig.10).

|

|

| A

coating knife, also known as doctor knife ensures uniform spreading

of the coating materials in the form of solutions, emulsions

or dispersions in water or an organic medium on the supporting

material, which is moved along by rollers. The coating is then

dried. Alternatively, the coating applied to the supporting

material may take the form of film of plastic, in which case

the process is called laminating.

|

|

| Metal

articles of complex shape can be coated with plastics by means

of whirl sintering process. The articles, heated to above

the melting point of the plastics, are introduced into a fluidized

bed of powdered plastics a rising stream of air in which the

powder particles are held in suspension, whereby a firmly

adhering coating is deposited on the metal by sintering.

|

|

|

o

DISCLAIMER o

CONTACT US |