Winding |

|

| The

term winding refers to the operation associated with hoisting

the mined mineral to the surface. In modern mines winding

is automated i.e. controlled by electrical contacts in conjunction

with acoustic and visual signaling and various devices to

ensure safety when men are being raised or lowered. All winding

systems embody the counterweight principle, with two cages

(or skips) moving in opposite directions one ascending while

the other descends.

|

|

|

The

basic characteristic of the winding gear are the winding engine

or motor, the headframe usually a lattice steel structure,

up to 200 ft. high, over the shaft, the winding rope and drum,

the cages or the skips, the intermediate gear whereby the

latter are connected to the rope, and cage guides in the shaft.

|

|

|

|

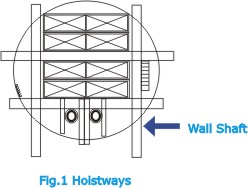

| Large-diameter

shafts of circular section up to 7 m (23 ft.) diameter –are

normally equipped with two sets of winding gear; there are

thus four hoistways (Fig.1), in each of which a cage moves

up and down. Steam-powered winding engines or electric winders

are employed, the latter usually being driven by direct-current

electric motors with Ward-Leonard control. Such motors may

have power ratings of as high as 12,000 KW and hoist coal

or other minerals at a rate of 10,000 tons per day from shafts

800 m (2600 ft) in depth. The hoisting speed in deep shafts

is about 22m/sec. (70-75 ft/sec.) with a 30-ton payload.

|

|

|

|

| The

winding operations are controlled by a device known as winding-speed

regulator. It calculates the hoisting speed in relation to

the distance traveled and more particularly limits the acceleration

of ascent and descent. In addition, every winding system includes

a depth indicator, which consists essentially of a screw spindle

along which a nut travels; the position of the nut on the

spindle indicates the position of the cage in the shaft. |

|

| This

device is linked to an overwind-prevention device, which actuates

a second brake (drop-weight brake) if the cage ascends too

high and the counter-balancing cage consequently descends

too low. In the event of overwinding, the cage is slowed down

and braked by such means as thickening the cage-guide rods

in the top part of the headframe. |

|

|

|

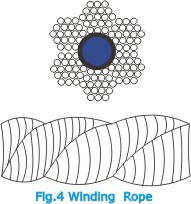

| Winding

ropes are composed of several strands which in turn consist

of cold-drawn steel wires of 2.5mm (0.1 in.) diameter, with

a tensile strength of 200 kg/mm2 (127 tons/in2)(Fig.4). Such

ropes may be as much as 100mm (4 in) thick and have breaking

loads of around 700 tons.

|

|

|

|

| |

|

| In

Britain, cage winding is still predominant in coal mining.

However, skip winding is progressively being introduced; it

is already extensively used in the United States and in various

continental countries. A skip is a guided steel or aluminum-alloy

box (Fig.5) which is automatically filled at the bottom of

the shaft and automatically discharged when it has been hoisted

aboveground. |

|

| The

advantage of skip winding is that a skip can carry a relatively

larger payload than a cage with tubs or cars; the proportion

of payload to total load can be raised by nearly 40% by substituting

skip for cage winding, and loading and unloading are faster.

In the main, there are two systems of winding gear: drum winding

and Koepe winding. |

|

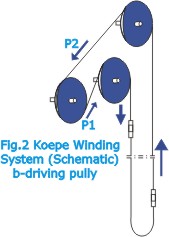

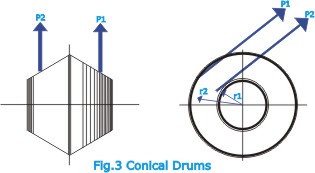

Of these,

drum winding is the more widely applied. The drum may be variously

shaped: cylindrical, conical, cylindroconical. The object

of the conical shape (Fig.3) is to equalize the driving torque

by using a smaller diameter of drum when exerting maximum

rope pull to lift and accelerate the cage (or skip). In Germany

and Holland the Koepe system (Fig.2) is generally preferred.

In this system the massive drum is replaced by a wheel with

one peripheral groove.

|

|

A single

winding rope lies in this groove, and all controlling forces

transmitted through the rope depend on the friction of the

rope in the groove. The cages (or skips) are suspended one

on each end of the rope, which passes over the Koepe wheel.

The system offers certain advantages and is more particularly

suitable for winding heavy loads from deep levels. |

|

|

o

DISCLAIMER o

CONTACT US |