Zinc |

|

|

The

chief ore zinc is sphalerite (ZnS), also known as the zinc

blende, which usually occurs in association with galena (PbS)

and smaller quantities of other metallic sulphides. Concentrates

with more than 50% zinc are produced by flotation. From these

the zinc can be obtained by various thermal reduction processes

or by leaching and electrolysis. In every case the process

must be preceded by complete roasting to convert zinc sulphide

into zinc oxide and thereby make it leachable or reducible

with carbon. |

|

| The

name of the metal zinc is unusual and, while vague in origin,

was probably first used by Paracelsus, a Swiss-born German

chemist, who referred to the metal as Zincum, in the 16th

century. These words in German apparently mean "tooth-like,

pointed or jagged part" and, as zinc metallic crystals

are needle-like, the derivation appears plausible. Zinc mines

of Zawar, near Udaipur, Rajasthan, were active during 1300–1000

BC. There are references of medicinal uses of zinc in the

Charaka Samhita (300 BC).

|

|

| The

Rasaratna Samuccaya (800 AD) explains the existence of two

types of ores for zinc metal, one of which is ideal for metal

extraction while the other is used for medicinal purpose.

Because of the low boiling point and high chemical reactivity

of this metal (isolated zinc would tend to go up the chimney

rather than be captured), the true nature of this metal was

not understood in ancient times.

|

|

| From

low-grade zinc ores and from intermediate products containing

zinc, such as flue dusts from lead and copper smelting, it

is possible to obtain zinc oxide by the so-called rotary process;

the material containing zinc is heated under reducing conditions

in a long rotary kiln i.e. a tubular cylindrical furnace which

is inclined and revolves on its longitudinal axis; the raw

material is fed in at the upper end and gradually makes its

way down to the lower end, acquiring a progressively higher

temperature on the way.

|

|

| In

the kiln the zinc is volatilized; in the upper part the zinc

vapor is burned to zinc oxide, which leaves the kiln along

with waste gases and is collected in a bag-filter plant. Zinc

production by dry processing presents particular difficulties

because zinc has a low boiling point (906 oC) and therefore

occurs only in gaseous form at the temperature necessary for

effecting the reduction (1300oC).

|

|

| |

|

| For

this reason reduction has to be carried out in closed vessels

or furnaces in which the zinc vapor can be condensed in the

absence of air. For thermal reduction the concentrate is roasted

a treatment that may be carried out in two stages multiple-hearth

furnace followed by sintering on a traveling grate or in a

single-stage operation in which a proportion of the roasted

material is fed back to the sintering machine. Sintering is

necessary for transforming the material into suitable lumps

to allow air to flow through it during the subsequent reduction

process.

|

|

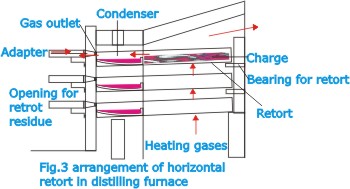

| Reduction

of the zinc oxide can be done by various methods. In the so-called

standard process, reduction is effected in horizontal retorts

in a retort furnace or distilling furnace (Fig.2), which comprises

a lower part containing regenerative chambers for preheating

the gas and combustion air and an upper part in which retorts,

arranged in tiers one above the other, are heated by the hot-flame

gases. A retort of this kind is a rectangular distilling vessel,

about 6or 7ft. long and about 1 ft. square in cross section.

It is made of fireclay and has only a short service life,

having to be renewed every four to six weeks.

|

|

|

|

| The

zinc vapor escapes from the retorts and is collected in the

condensers as liquid metal. At the end of about 20 hours the

process has been completed; the liquid zinc and zinc dust

are then removed from the condensers, and the residual matter

is removed from the retorts by special machines. Cleaning

out the retorts and recharging them takes about 4 hours, so

that the whole cycle can be repeated every 24 hours. In a

more recent development of the process a single large condensing

chamber is used instead of individual condensers.

|

|

|

|

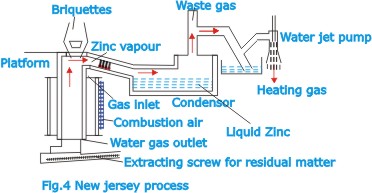

In

the New Jersey process (Fig.4) reduction is effected in large

vertical retorts about 14m (45 ft) high and of rectangular

cross section, lined with silicon-carbide bricks in the hottest

parts. The advantage over the horizontal retort method is

that reduction can be performed as a continuous operation.

The charge consist of briquettes made of a mixture of zinc

oxide material (roasted blende) and bituminous coal. The briquettes

are fed automatically to the resort, the residual matter being

extracted by a screw conveyor at the bottom. The mixture of

carbon monoxide and zinc vapor is discharged from the top

of the retort into a condenser, where the metal is precipitated

in liquid form.

|

|

There

have been many attempts to utilize electricity for the smelting

of zinc. The St. Joseph Lead Co. (U.S.A) has developed a successful

method of reducing zinc in an arc furnace (Fig.5). The process

is similar in principle to the retort method, except that

the heat is now supplied by the electric arc. Another fairly

recent development is the method employed at Avonmouth (Great

Britain), which has significantly affected the metallurgical

processing of lead as well as zinc.

|

|

|

|

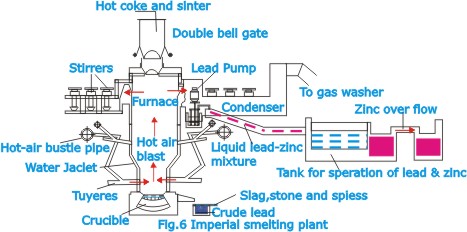

In

this method, known as the Imperial Smelting process, the two

melts are produced simultaneously from the oxides of zinc

and lead in a shaft furnace. The process is especially valuable

for dealing with ores in which sphalerite and galena occur

in intimate association with each other. The furnace is charged

with coke and a mixture of roasted lead and zinc ores, prepared

by a pressure sintering process. In the furnace, which is

really a form of blast furnace, the lead oxide is reduced

to molten metallic lead, which collects at the bottom.

|

|

The zinc

oxide is likewise reduced and forms zinc vapor, which is extracted

at the top of the furnace along with the combustion gases.

The vapor is passed to a condenser in which the cooling medium

is molten lead, in which the zinc dissolves. The zinc-in-lead

solution is then passed into a separator in which on cooling,

a layer of liquid zinc forms a top of the lead (this separation

is due to the fact that the solubility of zinc in lead diminishes

at the lower temperature). The lead is returned to the condenser,

and the zinc is further processed by refining.

|

|

The

lower part of the first column is heated. Impure zinc is fed

continuously into the top of the column and is vaporized as

it flows down through the heated trays. After further purification

by refluxing in the upper part of the column, the zinc vapor

(still containing cadmium but free of other impurities) is

passed to a condenser, whence it is fed to the top of the

second column, in which all the cadmium is driven off. Zinc

of 99.995% purity is condensed and drawn from the bottom.

Another widely used method of zinc production is by the leaching

of roasted zinc concentrates with acid and then depositing

the zinc by electrolysis from the solution thus obtained.

|

|

|

o

DISCLAIMER o

CONTACT US |