|

Engineering Materials |

|

|

Ferrous Materials : These materials contain iron as principal constituent e.g., cast iron, wrought

iron and various types of steels.

|

Non-ferrous Materials : These materials do not contain

iron as principal constituent e.g., aluminium, copper, zinc

etc. |

Non-metals : These non-metallic materials are of considerable

use in various fields of engineering e.g., rubber, polystyrene,

nylon etc. |

Elastic Limit : A material can withstand this greatest stress without permanent elongation when the load is

removed the sample will return to its original length.

|

Yield Point : This is the stress at which appreciable elongation occurs without increase in stress.

|

Ultimate Strength : It is the maximum stress required to break a specimen.

|

Modules of Elasticity : The ratio of stress to strain within the elastic limit. Modules of elasticity is a measure

of stiffness.

|

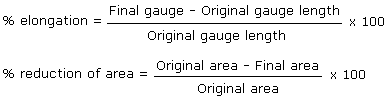

Elongation : The ratio of the increase in gauge length to the original gauge length which is expressed in percentage.

|

Ultimate Strain : The unit elongation at the specimen breaking point. Ultimate Strain is a measure of ductility.

|

Ductility and Brittleness : Ductility is a mechanical

property which is used to describe the ability of a metal to

deform plastically without fracture. It is most commonly measured

by means of elongation and reduction of area in the tensile

test.

In a gauge length of 50 mm if the percentage elongation is less

than 5, the material is usually classified as brittle.

|

Poisson's Ratio : The ratio of the transverse to the

longitudinal elastic strain in an axial member which is loaded

on its longitudinal axis. |

Stiffness : It describes ability of a metal to resist

deflection or formation. Stiffness is defined by Modulus of

elasticity. It is the ratio of stress to strain. |

Indentation Hardness : In metal working, resistance of penetration means hardness. It may also includes

resistance to scratching, abrasions or cutting. It is usually measured in terms of Brinell hardness number or Vicker's

pyramid number or Rockwell hardness number(scale B or C).

|

Fatigue : Description of the behavior of metals under

the action of alternating loads. It is distinguished from the

behavior under steady loads. It is the progressive and localized

structural damage that occurs when a material is subjected to

cyclic loading. |

Impact Strength : It is the ability of a material to

understand shock loading. |

Transverse Shear Strength : It is the value obtained by dividing the breaking load by the transverse shear

area. It is required in the designs of bolts, rivets, pin etc.

|

Torsion : The twisting of a material by force that turns one end of a bar about its longitudinal axis while

the other end is either clamped in a rigid fixture or twisted in the opposite direction. It makes shear stresses in

the material and occurs in such applications as propeller shafts, springs etc.

|

Damping Capacity : The ability of a material to absorb vibration. During a completely reversed cycle of stress, energy dissipated as heat by a unit volume of

the material. High damping capacity is required to reduce vibration and to reduce chatter in machine tools.

|

Creep : Creep is the tendency of a metal to move gradually or deform permanently under the influence of stresses.

It is more severe in materials that are subjected to heat for long periods, and near the melting point.

|

Aluminium : It manages electricity and heat well. It

has specific conductivity about 60% of that of copper, but less

tensile strength. Therefore a steel wire is incorporated when

making cables of aluminium, to provide strength. |

Solder : It is a fusible metal alloy which has a melting point or melting range of 90 to 450 °C means 200 to 840 °F.

There are three types of Engineering solders : Soft, Brazing and Silver.

|

White Metals : White metals are any of several lead-base or tin-base alloys, former being the Babbitt metals. Tin

base alloys are most ways superior to lead alloys but they are more costly.

|

|